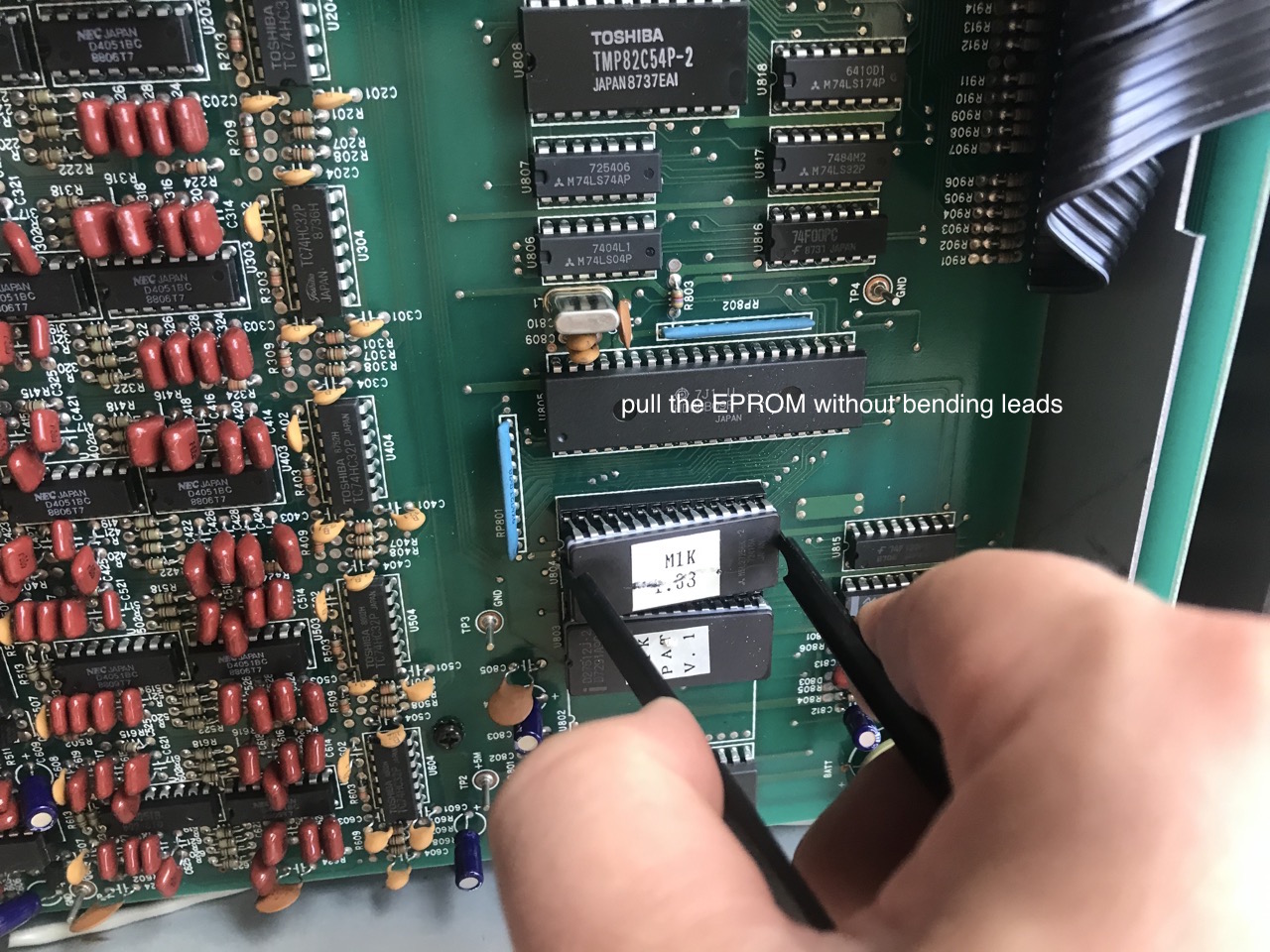

A customer once asked us many noobs questions on how to upgrade the Oberheim to the latest EPROM. Follow this process to upgrade your Oberheim .

Author Archives: alpesmachines

summer 2019 is here

Dear fellows,

The summer is here and holidays too ! We have been recently developing a Roland Chorus clone based on circuits of Juno 106/60, JX3P and Boss CExx series.

Prototypes have been tested and optimized, but, before a sale we need to make some marketing and publish some data for the early customers.

The Stereo One-O-Six chorus is ready to launch as a kit : front panel, printed circuit board, aluminium enclosure and a few parts (rest of the parts can be ordered online on famous webshop of electronics). If the interest is particularly high we will propose an industrial version of the product (SMD components).

We made some videos and editing those last days, so you should expect something particularly interesting to listen and watch.

The JuCe Chorus is postponed to a later date (certainly autumn of the year) as we can’t manage very products at the same time.

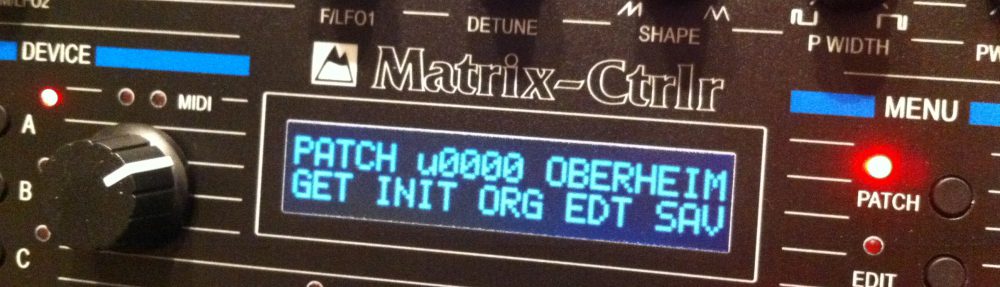

Notice that the Matrix Ctrlr is available in stock, still as a kit (with optional assembly service). There are a few kits left. Don’t wait too much to order yours ! We will not restock the deluxe edition.

Julien

RESTOCKING Spring2k19

Dear Fellows,

Several peoples ask when the Matrix Ctrlr Kit will be available. Well, we pause the run on the restocking to finish the design of a prototype PCB (JuCe Chorus, based on Boss CE300 and Roland Juno) and have some free time to enjoy skiing in the Alpes, but the ‘long to get’ parts are in stock. We just need the PCB, usually delivered in one week (express), and some paint job in Savoie (FR). We will open (pre)order in April 2019.

Besides that, we will certainly sell one or two Oberheim Matrix 1000 or 6 for those interested, with a discount on a Ctrlr. Please wait a new item in the shop.

We recently bought junk synths and restored them, we will create a vintage section soon.

Keep in mind that Alpes Machines activity is besides a full time daily job and particularly time-consuming. We need to sleep too 😉

Cheers

Oberheim Matrix EPROM

We restocked a few eproms for your Oberheim synthesizer. Available for Matrix 6/6R and Matrix 1000 in the shop.

Happy 2019 !!!

Alpes Machines wish you all the best for 2019 with lots of success and joy in the music.

The Matrix Ctrlr is still interesting lots of people, hence it is currently sold out. We will restock a few kits in the next weeks, don’t hesitate to contact us to reserve yours.

Besides we have started the development of a Chorus unit based on Roland Juno and Boss CE300 circuitry with additional features that should interest many peoples.

More infos should be announced on Youtube and Facebook next month.

A new shop page is also on the bench. We thank you for your kind support and confidence through the last 2 years. We love you 🙂

BLACK FRIDAY 2018

Get a 20% discount on all Alpes Machines products including the assembled Matrix Ctrlr.

Use coupon code “BLACK2018” at check out !

there are more than 10 kits available in stock

Matrix Ctrlr : in stock

We have restocked enough parts to supply 15 kits of the Matrix Ctrlr. The paint is drying in the garage 😉

Besides, we are thinking about selling PCB & stickers only at a very interesting price for all the greedy peoples out there LOL. More seriously, preparing kits is lots of time, time that could be used to develop new interesting device like a Juno106 chorus digitally controlled (it’s on the bench).

If you are an experienced DIYer located in the USA or UK, we are interested by your services for soldering : give a shoot !

Matrix Ctrlr 1.05 : new features

- New memory management : the name & tone of a patch, the arp parameters, the unison detune are organized a bit differently, allowing direct upload of patches from the matrix 6/ 1000 to the Ctrlr without a computer. An auto initialization sequence on boot formats the memory if the eeproms are new. A hidden menu allows to format the Ctrlr to factory state.

- Test mode : pressing F1 & F2 while powering allows to test the unit during building/soldering.

- Several Matrix synths controlled at the same time : now control 4 units independently.

- Randomizer on tone parameters : press a button to create random values on DCO or ENV for example (a customer request).

- Triggers : external analog sources to trigger the arp/seq are now supported. Even a general midi rimshot (37) note message can be used !

- Complete debug of the user interface : DCO2 Pulse doesn’t provide random press anymore (on PCB earlier rev1.2). Some random controllers corrected.

- Complete integration inside a midi environnement and a DAW with Local Control on/off.

- Complete sysex/control change translator implemented.

- Zone : Midi patchbay on 4 channels, with transpose, range and redirection.

- System config sysex.

- Ctrlr less verbose : smoothness with Matrix when editing it.

The firmware is available on Github

NOTA : backup your patches before upgrading !

It has been tested on Logic Pro 9 with one Matrix 6 Keyboard, one Matrix 6 rack and 1 Matrix 1000 rack. Beware of the midi loops ! Setup correctly your gear to manage 4 channels and remind you that sysex don’t have a channel.

Firmware update 1.04 : final release

First it has been discovered that the Matrix 6 sends curious Note On messages instead of Note Off if you load a new patch while any keys are pressed, so it is strongly advised to send Notes using a MIDI Master keyboard !

Many of the features are working as expected, from the beginning.

The only real bug that has been found applies to customers with PCB v1.2 or earlier: pressing the DCO2 Pulse switch sometimes leads to random press of the other switches. It has been solved by scanning twice and comparing the results. All customers are advised to update to final releases 1.04.

Before updating, as the memory management has been completely rewritten to be faster, it is an absolute necessity to back up all your patches first by using the DuMP function in the CFG Menu (since 0.99x).

Once loaded, 1.04 will format all the memory of the Matrix Ctrlr, erasing datas, while booting. You can then reload the 8 factory banks + 2 custom banks into the Ctrlr via SysEx.

You now can save your Matrix6/1000 personal bank directly to the Ctrlr without a computer and a third party software (Sysex librarian or C6). To do this, connect the Midi out of the Matrix1000 to Core In, select your Matrix1000 (A, B, C or D, depending of your configuration), and in page 2 of the PATCH Menu press GET. The Matrix1000 will send the selected bank to the Ctrlr.

Now a bit of technical detail (and maths):

A Matrix Patch is [134] bytes :

- [8] first Bytes are used to store the Name,

- [126] following Bytes are used for the Tone parameters.

The Ctrlr stores those patch parameters in four 24LC512 EEPROMs.

Writing to the 24LC512 EEPROMs uses a fast method (known as “paging”) where we write 128 bytes in one shot. An EEPROM has 512 pages of 128 bytes each, thus the Tone parameters are stored on odd EEPROMs, while the names are stored on matching even EEPROMs with the same ‘page’ reference.

While it should be clear that we could store 1024 (512×2) patches with 4 EEPROMs, we have instead to mimic the Matrix 1000 and allow only 1000 patches. The remaining free space on each page of the matching even EEPROM is used to store Unison, ARP and Sequence associated to each patch.

Because the Ctrlr is too slow to write on two external EEPROMs between two patches sent directly from the Matrix 1000 via MIDI, we decided to save only the useful tone parameters on the odd EEPROM, and it works rather well. Nevertheless, the Matrix 1000 sends patches with names like “BNK1: 02” that are completely useless.

The Ctrlr saves them as “MTRX-102” on the EEPROM pairs with a default Unison detune of 0, default Arp Parameters and a default Sequence. You are free to edit name, unison, arp and sequence and store them after using SAV. When DuMPing the Ctrlr memory, several SysEx messages associated to a patch are generated in this order: a SysEx message containing the Unison Detune value, a SysEx message containing the Arp Parameters & the Sequence and a SysEx message containing the Matrix patch, identical to those generated by Oberheim Matrix 6/1000.

This order is important and it permits to save all the memory with your favorite SysEx librarian in order to create a backup useful to the Ctrlr. This represents 3012 SysEx messages (1000 patches + 1000 unison + 1000 arp/seq + 10 Change bank message + 1 Matrix master parameters + 1 system config sysex) so a computer is highly recommended to store so much data.

New shop : cart

The Matrix Ctrlr is about to be back in shop, certainly next week. Lots of components, lots of metal in stock. “Sticker ready for friday” according to the manufacturer in my town.

The Matrix Ctrlr shop page is ready but hidden to public for the moment. Great news, there is now a Paypal cart, with coupons ! I expect to open it next Monday. With a surprise for the Facebook fans of Matrix6/1000

I am also very excited to play with my new toy the Microstop, imported from USA through UK and used in aircrafts manufacturing process.

A new feature has been implemented on the PCB in order to sync to pure analog gear. Any positive DC pulse is recognized by the Ctrlr to control the Arpeggiator. Some lines of code to indicate to the Ctrlr to monitor external triggers instead of Midi Clock (hence J1 and J2 jacks on front panel).

In the meantime i will clean up the code and push it on Github. Remainder : new firmware is simply uploaded using USB. A dedicated page will be created regarding this very useful feature, so that previous customers can make the circuit at home (Moog published the schematic years ago) :

Well, my week end is fulfilled ^^